Several problems can require healthy intervention. They might include sand, scale, or wax collecting in the well, mechanical issues like valves and gauges failing, or perforating the wellbore to install or remove equipment.

A light intervention system is the most effective solution for many of these issues. These systems do not require a drilling BOP and can be deployed from a service vessel.

Improved Safety

To ensure wells live out their expected lifetime, regular interventions are needed. These operations allow operators to clear wells of sand and adjust plugs or valves. Traditionally, these operations were carried out by either wireline or coiled tubing.

Both systems can perform various tasks, but they differ in terms of capabilities and rigs. Unlike coiled tubing, an offshore wireline system can land pressure control packages and lubricators on top of subsea trees, where tools can be lowered.

These electrification, automation, and digitalization systems lay the groundwork for a new organizational structure and operation. A reduced workforce, safer maintenance procedures, and a lower risk of destroying the well are just a few advantages that these improvements can bring about. A leading integrated solution is digital slackline, which merges surface acquisition equipment with standard slackline equipment on a single reel. This eliminates the need to shuffle surface equipment between operations, saving time.

Greater Flexibility

As a global society rapidly develops and modernizes, a growing need for clean energy drives exploration for new oilfield reserves. The oil demand, however, needs to catch up on existing resources fast. This has resulted in a surge in demand for suitable subsea well intervention and drilling equipment to help maintain, repair and replace components.

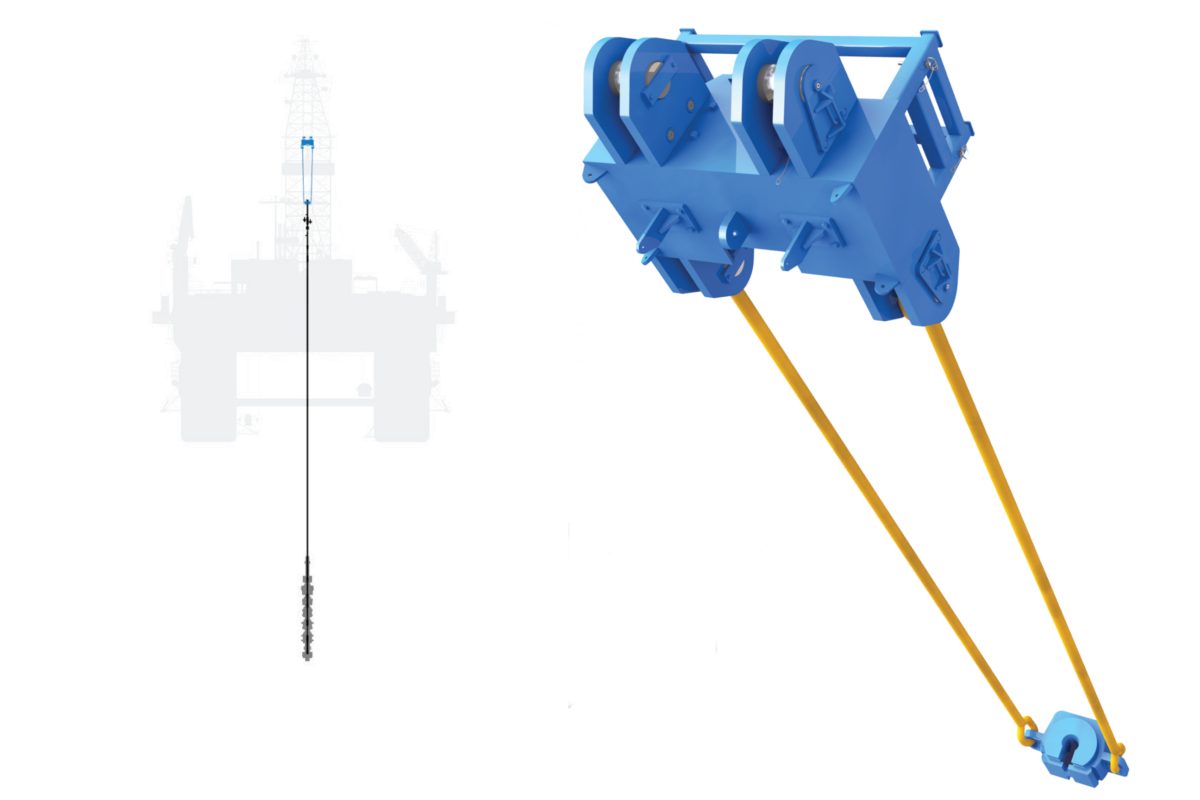

To perform these services, a workover rig is required. A rig can clear blockages in the good bore by lowering an electric tool on the end of a wire or pipe, called a slackline. It can also adjust valves and plugs in the well. The slackline can even send back real-time logging data to help engineers determine the well’s condition without pulling the tool up from the wellbore. GE’s digital slackline solution optimizes the main cost drivers of traditional intervention operations, such as reducing the number of surface equipment that must be shifted between jobs and simplifying the rig-up. This enables faster completion and reduced downtime.

Reduced Time

The single wire of a slackline conveys tools and sensors into and out of the well, enabling operators to carry out tasks such as removing sand or paraffin from subsurface control valves. The slackline is reeled on and off of a hydraulically driven drum, and a heavier cable may be deployed from a second one if the tensile strength required to complete an operation exceeds that of the slackline.

Innovative coiled tubing (CT) technologies enable operations to run more quickly, giving operators valuable real-time information as they work. For example, an operator using the tool to access inflow control devices (ICDs) in horizontal wells could shift 10 ICD sleeves within six hours versus over 12 hours with conventional means.

Conducting less invasive interventions also reduces the time and cost of an overall operation. This is especially important when bringing aging well infrastructure to its end of life through Plug & Abandonment, which can be a significant undertaking for the industry.

Increased Efficiency

Well-intervention operations are usually required to fix a multitude of issues. These range from pumping acid to dissolve chemicals clogging the reservoir; to perforating the wellbore to recover additional reserves; or even removing sand, scale, and wax to make it easier for the well to produce.

Slickline and e-line are essential for many of these light intervention jobs. Slickline is an unbraided wire that delivers tools to the bottom of the well. At the same time, e-lines are braided and can carry a variety of mechanical and electrical devices for monitoring and data collection.

Using a single vessel to perform CT and production logging eliminates the need for surface equipment rig-up between operations, eliminating costly delays and reducing operational footprints. This also enables a broader range of P&A campaigns and reduces cost and operational risk. In addition, it supports the development of portfolios and proper planning to allow for greater RLWI through more effective sound optimization.